How it began...

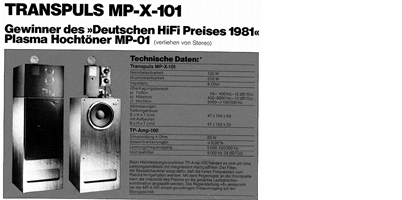

Reiner Haas, former Manager of Magnat, was visiting the CES (Consumer Electronic Show) 1978 in Chicago, where he heared the first time a plasma speaker and was facinated. He spontaneously bought the license to build them himself. But there should still be a long way to go before the finished product under the name MAGNAT was availible.

It took 3 years of development until the first commercial MP-01 was ready. The reason for this was that Magnat want to use transistors insted of tubes and it schould be a omnidirectional speaker without a horn.

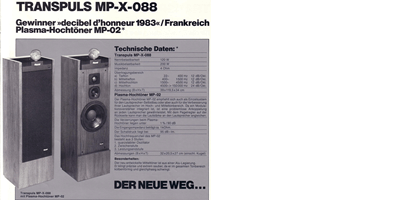

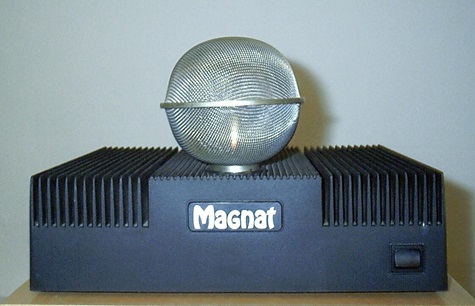

Transplus MP-X-101 the first MAGNAT speaker with a plasma tweeter

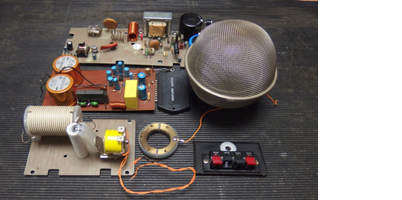

The MP-01 system consits of two units. the RF part with the mesh case on top where the plasma flame burns and a second housing for the modulation and active crossover.

On the picture we see that the midrange is build with two tweeters to mach the plasma. I know from people out of Magnat that it was difficult to match the fast plasma to the midrange.

Also the bass drivers were not the best in these days. A passive crossover for bass and midrange was also on top of the box.

Demonstration Video in slow motion starting the flame

MP-02 was the new development

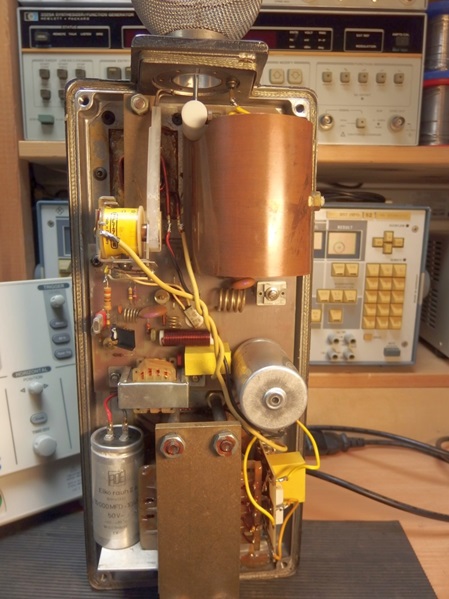

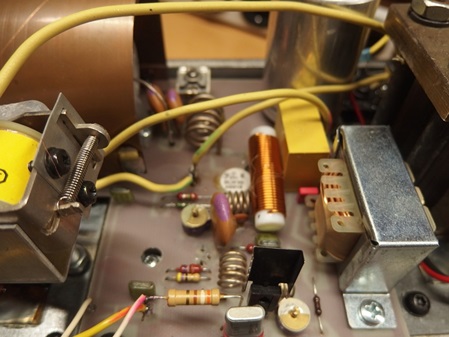

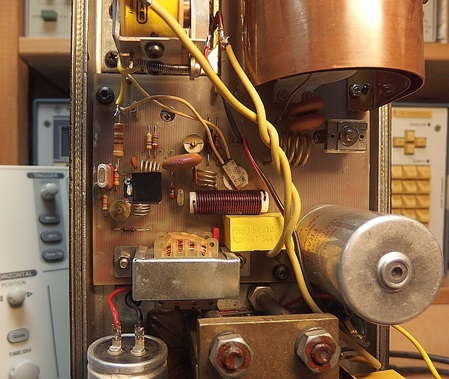

The Mp-02 had a new improved RF section and is able to run as a standalone tweeter. All parts oscillator, modulation, power supply and active crossover were build in one case.

So it was easy to set the MP-02 on different cabinets. The MP-X-066 and the MP-X-088.

The difference was in the midrange. MP-X-066 were build with one midrange speaker. The MP-X-088 had two midrange speakers one for the low and one for the high midrange.

As the MP-02 run separately it can easy combined with other loudspeakers. There are some Quad ESL55 owners combining their systems with the MP-02. Because of it's omnidirectional irradiation the MP-02 it is a perfect match to the Quads. The build in active crossover starts the tweeter from about 5khz. On the back we have the input terminals, sensitivity knob and main power input.

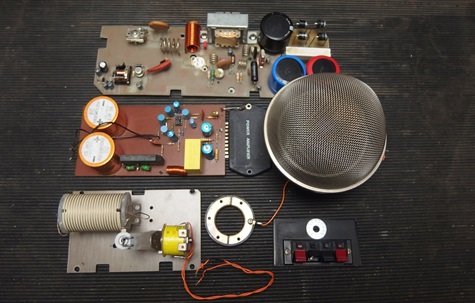

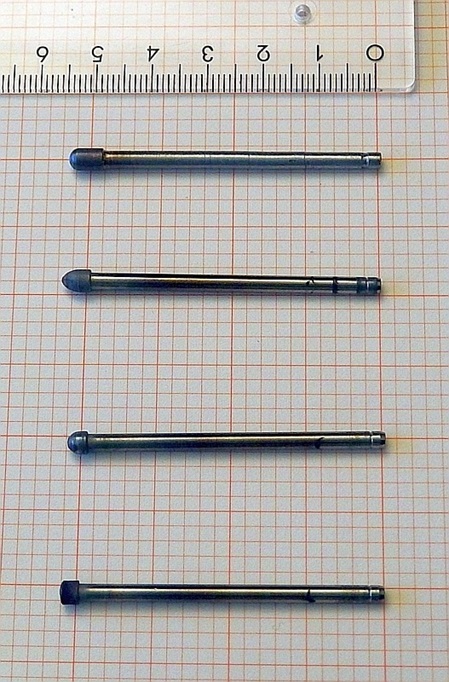

Electrode

Wear part is the electrode. Magnat guaranteed a lifetime of 500 hours. The electrodes are long sold out by the manufacturer. So I did a research on this to help other owners. The proper material is Kanthal® A1. There is only one manufacturer - Kanthal® in Sweden.

I am now able to make electrodes out of this special material.

The picture left shows different electrodes. From bottom to top - old original worn out electrode the tip is burned away, old original electrode new shaped on the lathe, original electrode with good tip, and on the top electrode which I have made out of Kanthal®. I make the tip always a little bigger to give the electrode more lifetime. These are MP-02 electrodes, MP-01 electrodes are longer.

If you need electrodes feel free to contact me.